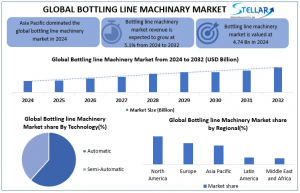

Bottling Line Machinery Market Projected to Hit USD 6.39 Billion by 2032, Expanding at a CAGR of 5.1% Forecast 2025-2032

Global bottling line machinery market size was valued at USD 4.74 billion in 2024 and is expected to reach USD 6.39 billion in 2032 at a CAGR of 5.1%.

Automation, precision, and sustainability are transforming the bottling line machinery market, empowering manufacturers to meet evolving demand with speed and reliability.”

ATLANTA, GA, UNITED STATES, July 14, 2025 /EINPresswire.com/ -- Bottling Line Machinery Market - The Future of High-Speed Packaging— Dharati Raut

Bottling Line Machinery Market size was valued at USD 4.74 billion in 2024 and is expected to reach USD 6.39 billion in 2032 at a CAGR of 5.1%.

Bottling Line Machinery Market Overview

Bottling line machinery has developed from a manual system to an automated, artificial intelligence (AI)-driven bottling process. Today's bottling lines create more accuracy, waste less, and meet the stricter standard for safety as you try to accommodate customers' requests for recyclable, sustainable packaging. Not only are bottling line machines being changed for good because of constantly improving technology - volumetric automatic bottle filling, high pressure processing (HPP), smart labeling, artificial intelligence (AI) enabled fill level control, etc. - but also the industry leaders such as Krones AG, SACMI, and GEA Group are changing the definition of performance with electricity - saving machines, advanced seaming, and the ability to observe the process through cameras in real-time.

The growth of ready-to-drink beverages further emphasizes this trend. The Distilled Spirits Council of the United States found that RTD spirits would be the fastest-growing spirits category by revenue globally in 2023, demonstrating how consumer trends directly influence demand for faster, safer bottling solutions.

To know the most attractive segments, click here for a free sample of the report: https://www.stellarmr.com/report/req_sample/bottling-line-machinery-market/2604

Key Market Dynamics

What’s Driving Growth

Automation and AI-Powered Solutions

Today’s bottling industry applies automation and AI technology for increased productivity and efficiency. Smart sensors and IoT devices monitor fill levels, provide error alerts, and power predictive maintenance. Robotic arms and advanced control systems reduce downtime and increase throughput. Utilizing these technologies results in consistency of product, greater control of labor costs, decreased waste, and consistent and reliable performance of the bottling line in high-speed operations.

The Rise of Sustainable Packaging

Sustainability is the future of the bottling industry. An increasing number of crafters and producers are obtaining recyclable, compostable and biodegradable packaging due to rigid regulations and the availability of undefined bottles. Energy-efficient machinery and smart processes reduce waste and resource utilization. Eco-friendly initiatives protect the environment, expand the brand name, and provide access to new markets interested in low or responsibly packaged product alternatives.

Need of Fast and Efficient Bottling Lines

The need for slow-to-fast packaged beverages, along with sterile products and are boosting the demand for faster and more precise bottling lines. Obviously, with the introduction of advance rotary and inline bottling systems filling and sealing thousands of units/hour, were also able to produce bottled water, flavored water, and pharmaceuticals faster than ever before. Advanced bottling technology has increased production output, assists in accuracy, reduce waste and labor costs and of course helps with the reliable and timely delivery to market.

What Are the Challenges

First Capital Outlay: Smart technology and automation demand a considerable first capital outlay. For manufacturers, this can be very daunting, but the long-term benefits, including labor savings and increased throughput, must be carefully balanced. Automated processes can introduce productivity gains, but can also create maintenance cycles that require attention to other tasks should not impact availability.

Technical Skills and Maintenance: Automation and advanced smart equipment can require skilled operators and occasionally a multi-modal approach to maintenance. The technical team will need proper industry training and ongoing technical support in order to successfully operate equipment, deploy software updates, and troubleshoot challenges in order to have each system operate smoothly and without incident. In more sophisticated bottling lines, if the expertise and preventive maintenance this technology requires are not present, then this role will be more challenging, and companies run the risk of unexpected breakdowns, which increases repair costs and production delays.

Regulatory Barriers: There are strict regulations governing bottling operations - both environmental for all food contact substances, and safety regulations such as NSF/ANSI 18. Indeed, adhering to these regulations will typically increase operational expenses. However, it also opens up opportunities for 'premium product' positioning in the product market. By meeting high regulatory benchmarks, companies can improve brand image, brand equity, safer packaging, and market access for brands that have a need for a superior quality assurance standard.

Regional Insights

North America: Still the Major Power

North America continues to deliver the largest share of market revenue due to a well-established, capable manufacturing base, as well as strict safety standards. The beverage industry in the U.S. is still expanding in size and scope, bringing with it a wider variety of bottled IoT-enabled equipment, an ever-increasing number of cloud-enabled monitoring capabilities, and a range of innovative packaging alternatives.

Europe: Sustainability and Innovation

Europe’s push for regulatory sustainability has generated demand for smart and efficient bottling lines. Producers are making carbon-neutral producers their goal, using biodegradable products as their packaging to accomplish the level of performance outlined by EU requirements.

Asia-Pacific: The Fastest Growth

Emerging markets such as China, India, and Southeast Asia are investing heavily in the modernization of packaging lines to support explosive growth in urban populations and the subsequent demand for packaged products that are safe and affordable.

To know the most attractive segments, click here for a free sample of the report: https://www.stellarmr.com/report/req_sample/bottling-line-machinery-market/2604

Key Players Shaping the Market

Top companies leading this transformation include:

Krones AG (Germany)

Tetra Pak (Sweden)

KHS GmbH (Germany)

Sidel Group (Italy)

Bosch Packaging Technology (Germany)

Coesia S.p.A. (Italy)

GEA Group (Germany)

Sacmi Imola S.C. (Italy)

ProMach Inc. (USA)

Syntegon Technology GmbH (Germany)

These players are competing on technology innovation, product quality, and sustainability. Their R&D pipelines focus on AI-driven diagnostics, automatic washers, advanced stretch blow molding, and remote quality control.

Application Areas: Where Demand Is Rising

Beverages: Carbonated drinks, RTDs, flavored water, and energy drinks.

Pharmaceuticals: Sterile liquid packaging where hygiene and accuracy are paramount.

Food: Bottling for sauces, dressings, and dairy alternatives.

Cosmetics & Personal Care: Packaging for perfumes, skincare, and haircare.

Chemicals: Specialized bottling for cleaning agents and solvents.

Key Takeaways

The Global bottling line machinery market is anticipated to reach USD 6.39 billion by 2032 with a 5.1% compound annual growth rate. The long-term return on investment will come from the focus on automation, sustainability, and smart technologies. North America and Europe are the biggest markets, but the highest growth potential is seen in the Asia-Pacific region. Vendors investing in IoT, AI, and energy efficiency will exceed expectations in meeting the challenges of changing needs, consumers and regulations.

FAQs

What is driving the global bottling line machinery market growth?

Key drivers include automation, smart tech integration, sustainability demands, and rising consumption of bottled beverages and sterile products.

Which regions dominate the bottling line machinery market?

North America holds the largest share, while Asia-Pacific is the fastest-growing region due to rapid industrialization and packaging demand.

What technologies are transforming bottling lines?

AI-powered fill control, IoT-enabled monitoring, smart sensors, volumetric filling machines, and HPP are revolutionizing bottling operations.

What industries use bottling line machinery?

Beverage, pharmaceutical, food, cosmetics, and chemicals all rely on modern bottling solutions to ensure safety, speed, and sustainability.

What are the biggest challenges for bottling line manufacturers?

High upfront costs, technical skill requirements, regulatory compliance, and the need for continuous innovation remain key hurdles.

Related Reports:

Party Supplies Market: https://www.stellarmr.com/report/party-supplies-market/2724

Upcycled Fashion Market: https://www.stellarmr.com/report/upcycled-fashion-market/2680

Outdoor Furniture Market: https://www.stellarmr.com/report/outdoor-furniture-market/2660

Disposable Cutlery Market: https://www.stellarmr.com/report/disposable-cutlery-market/2651

Body Dryer Market: https://www.stellarmr.com/report/body-dryer-market/2636

About Stellar Market Research:

Stellar Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include medical devices, pharmaceutical manufacturers, science and engineering, electronic components, industrial equipment, technology and communication, cars and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Stellar Market Research:

S.no.8, h.no. 4-8 Pl.7/4, Kothrud,

Pinnac Memories Fl. No. 3, Kothrud, Pune,

Pune, Maharashtra, 411029

sales@stellarmr.com

Lumawant Godage

Stellar Market Research

+ +91 9607365656

email us here

Visit us on social media:

LinkedIn

Instagram

X

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.